Kayan aikin carbide na siminti sun fi yawa a cikin kayan aikin injin CNC. A wasu ƙasashe, sama da kashi 90% na kayan aikin juyawa da kuma sama da kashi 55% na kayan aikin niƙa an yi su ne da carbide na siminti. Bugu da ƙari, ana amfani da carbide na siminti don ƙera kayan aikin gabaɗaya kamar injinan haƙa da masu yanke fuska. Amfani da carbide na siminti yana ƙaruwa a cikin kayan aikin rikitarwa kamar reamers, injinan ƙarshe, masu yanke gear matsakaici da manyan modulus don ƙera saman haƙoran da suka taurare, da kuma buroshi. Ingancin yanke kayan aikin carbide na siminti ya ninka na kayan aikin ƙarfe mai sauri sau 5 zuwa 8. Adadin ƙarfe da aka cire a kowace raka'a na abun ciki na tungsten ya ninka na HSS sau 5. Saboda haka, amfani da carbide na siminti sosai a matsayin kayan aiki yana ɗaya daga cikin hanyoyin da suka fi tasiri don amfani da albarkatu yadda ya kamata, inganta yawan aiki, da haɓaka fa'idodin tattalin arziki.

Rarraba Kayan Aikin Carbide Mai Siminti

Dangane da babban sinadarin sinadarai, za a iya raba carbide mai siminti zuwa carbide mai siminti bisa tungsten carbide da kuma carbide mai siminti bisa titanium carbonitride (Ti(C,N)), kamar yadda aka nuna a Jadawali na 3-1.

Carbide mai siminti bisa tungsten carbide ya ƙunshi:

Tungsten-cobalt (YG)

Tungsten-cobalt-titanium (YT)

Tare da ƙarin carbides masu wuya (YW)

Kowanne nau'i yana da nasa fa'idodi da rashin amfani. Ƙarin carbide sun haɗa da tungsten carbide (WC), titanium carbide (TiC), tantalum carbide (TaC), niobium carbide (NbC), da sauransu, tare da cobalt (Co) shine matakin haɗa ƙarfe da aka fi amfani da shi.

Carbide mai siminti wanda aka yi da siminti na titanium carbonitride galibi ya ƙunshi TiC (wasu tare da wasu carbides ko nitrides da aka ƙara), tare da molybdenum (Mo) da nickel (Ni) a matsayin matakan ɗaure ƙarfe da aka saba amfani da su.

Dangane da girman hatsi, ana iya rarraba simintin carbide zuwa:

Carbide mai siminti na yau da kullun

carbide mai siminti mai laushi

carbide mai siminti mai laushi sosai

A cewar GB/T 2075—2007, alamomin haruffan sune kamar haka:

HW: Carbide mai siminti wanda ba a rufe shi ba wanda galibi yana ɗauke da tungsten carbide (WC) mai girman hatsi na ≥1μm

HF: Carbide mai siminti wanda ba a rufe shi ba wanda galibi yana ɗauke da tungsten carbide (WC) mai girman hatsi <1μm

HT: Carbide mai siminti wanda ba a rufe shi ba wanda ya ƙunshi titanium carbide (TiC) ko titanium nitride (TiN) ko duka biyun (wanda kuma aka sani da cermet)

HC: Carbides ɗin da aka ambata a sama masu siminti tare da shafi

Ƙungiyar Ƙasa da Ƙasa don Daidaitawa (ISO) ta rarraba carbide masu siminti zuwa rukuni uku:

Ajin K (K10 zuwa K40):

Daidai yake da ajin YG na China (wanda galibi ya ƙunshi WC-Co)

Ajin P (P01 zuwa P50):

Daidai yake da ajin YT na China (wanda galibi ya ƙunshi WC-TiC-Co)

Ajin M (M10 zuwa M40):

Daidai yake da ajin YW na China (wanda galibi ya ƙunshi WC-TiC-TaC(NbC)-Co)

Ana wakiltar maki na kowane rukuni da lamba tsakanin 01 da 50, wanda ke nuna jerin ƙarfe daga mafi girman tauri zuwa mafi girman tauri, don zaɓar a cikin hanyoyin yankewa daban-daban da yanayin injin don kayan aiki daban-daban. Idan ya cancanta, ana iya saka lambar tsaka-tsaki tsakanin lambobin rarrabuwa guda biyu da ke maƙwabtaka, kamar P15 tsakanin P10 da P20, ko K25 tsakanin K20 da K30, amma ba fiye da ɗaya ba. A cikin lokuta na musamman, ana iya ƙara raba lambar rarrabuwa ta P01 ta hanyar ƙara wani lamba da aka raba ta hanyar maki na decimal, kamar P01.1, P01.2, da sauransu, don ƙara bambanta juriyar lalacewa da tauri na kayan don ayyukan kammalawa.

Aikin Kayan Aikin Carbide Mai Siminti

1. Tauri Carbide mai siminti yana ɗauke da adadi mai yawa na carbide masu tauri (kamar WC, TiC), wanda hakan ke sa taurinsa ya fi na ƙarfe masu sauri. Da yawan tauri na carbide mai siminti, to yana da kyau a sami juriyar sawa, wanda gabaɗaya ya fi na ƙarfe mai sauri girma.

Mafi girman matakin haɗa cobalt, haka nan ƙarancin taurin ƙarfe.

Tunda TiC ya fi WC tauri, ƙarfen WC-TiC-Co yana da tauri mafi girma fiye da ƙarfen WC-Co. Da yawan abubuwan da ke cikin TiC, haka nan ƙarfin tauri ya fi yawa.

Ƙara TaC zuwa gaurayen WC-Co yana ƙara tauri da kimanin HV 40 zuwa 100; ƙara NbC yana ƙara shi da HV 70 zuwa 150.

2. Ƙarfi Ƙarfin lanƙwasa na simintin carbide kusan 1/3 zuwa 1/2 ne kawai na kayan ƙarfe masu saurin gudu.

Mafi girman sinadarin cobalt, haka nan ƙarfin ƙarfen yake.

Alloys da ke ɗauke da TiC suna da ƙarancin ƙarfi fiye da waɗanda ba su da TiC; yawan abun ciki na TiC, haka nan ƙarfin yake ƙasa.

Ƙara TaC zuwa carbide mai siminti na WC-TiC-Co yana ƙara ƙarfin lanƙwasa kuma yana ƙara juriyar gefen da ke gaba ga fashewa da karyewa. Yayin da yawan TaC ke ƙaruwa, ƙarfin gajiya kuma yana ƙaruwa.

Ƙarfin matsewa na carbide mai siminti ya fi na ƙarfe mai saurin gudu da kashi 30% zuwa 50%.

3. TauriTuri na simintin carbide ya yi ƙasa da na ƙarfe mai saurin gudu sosai.

Alloys da ke ɗauke da TiC suna da ƙarancin tauri fiye da waɗanda ba su da TiC; yayin da abun cikin TiC ke ƙaruwa, tauri yana raguwa.

A cikin ƙarfen WC-TiC-Co, ƙara adadin TaC mai dacewa zai iya ƙara tauri da kusan kashi 10% yayin da yake kiyaye juriyar zafi da juriyar lalacewa.

Saboda ƙarancin tauri, carbide mai siminti bai dace da yanayin da ke da ƙarfi ko girgiza ba, musamman a ƙananan saurin yankewa inda mannewa da guntuwar suka fi tsanani.

4. Halayen Zafi na ZafiHanyoyin da ke amfani da siminti wajen sarrafa zafin carbide sun ninka na ƙarfe mai saurin gudu sau 2 zuwa 3.

Tunda ƙarfin wutar lantarki na TiC ya yi ƙasa da na WC, ƙarfen WC-TiC-Co yana da ƙarancin ƙarfin wutar lantarki na thermal fiye da ƙarfen WC-Co. Da yawan abubuwan da ke cikin TiC, haka nan ƙarfin wutar lantarki na thermal ke raguwa.

5. Juriyar Zafi Carbide mai siminti yana da juriyar zafi fiye da ƙarfe mai sauri kuma yana iya yin yankewa a 800 zuwa 1000°C tare da juriya mai kyau ga nakasar filastik a yanayin zafi mai yawa.

Ƙara TiC yana ƙara taurin zafin jiki mai yawa. Tunda zafin laushi na TiC ya fi na WC girma, taurin gami na WC-TiC-Co yana raguwa a hankali tare da zafin jiki fiye da gami na WC-Co. Da yawan TiC da ƙarancin cobalt, haka raguwar take.

Ƙara TaC ko NbC (tare da yanayin zafi mai laushi fiye da TiC) yana ƙara tauri da ƙarfi a yanayin zafi mai yawa.

6. Halayen Hana Mannewa Zafin mannewa na carbide mai siminti ya fi na ƙarfe mai sauri girma, wanda hakan ke ba shi juriya ga lalacewar mannewa.

Zafin mannewa na Cobalt da ƙarfe ya yi ƙasa da na WC; yayin da yawan sinadarin cobalt ke ƙaruwa, zafin mannewa yana raguwa.

Zafin mannewa na TiC ya fi na WC girma, don haka ƙarfen WC-TiC-Co yana da zafin mannewa mafi girma (kimanin 100°C sama da ƙarfen WC-Co). TiO2 da aka samar a yanayin zafi mai yawa yayin yankewa yana rage mannewa.

TaC da NbC suna da yanayin zafi mafi girma fiye da TiC, wanda ke inganta halayen hana mannewa. Ƙaunar TaC ga kayan aikin hannu ƙalilan ne kawai zuwa kashi goma na WC.

7. Daidaiton Sinadarai Juriyar lalacewa na kayan aikin carbide mai siminti yana da alaƙa da daidaiton jiki da sinadarai a yanayin zafi na aiki.

Zafin iskar shaka na simintin carbide ya fi na ƙarfe mai saurin gudu girma.

Zafin iskar shaka na TiC ya fi na WC girma sosai, don haka ƙarfen WC-TiC-Co yana samun ƙarancin nauyin iskar shaka a yanayin zafi mai yawa fiye da ƙarfen WC-Co; yawan TiC, ƙarfin juriyar iskar shaka.

Zafin iskar shaka na TaC shi ma ya fi na WC, kuma ƙarfe masu ɗauke da TaC da NbC sun inganta juriya ga iskar shaka mai zafi. Duk da haka, yawan sinadarin cobalt yana sauƙaƙa iskar shaka.

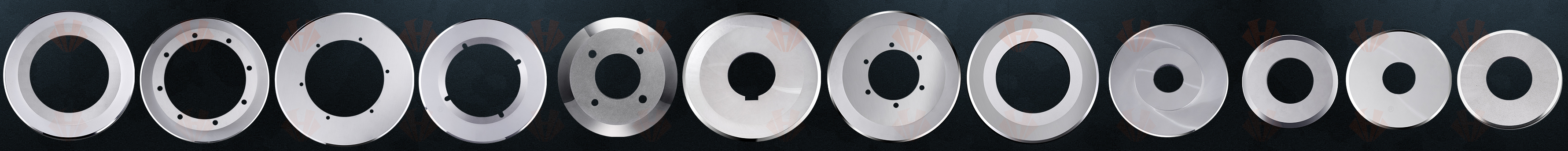

Me yasa ake buƙatar Chengduhuaxin Carbide?

Chengduhuaxin Carbide ya shahara a kasuwa saboda jajircewarsa ga inganci da kirkire-kirkire. Ruwan kafet ɗinsu na tungsten carbide da ruwan wukake masu ramin tungsten carbide an ƙera su ne don ingantaccen aiki, suna ba masu amfani da kayan aikin da ke samar da sassaka masu tsabta da daidaito yayin da suke jure wa wahalar amfani da masana'antu. Tare da mai da hankali kan dorewa da inganci, ruwan wukake masu ramin Chengduhuaxin Carbide suna ba da mafita mai kyau ga masana'antu da ke buƙatar kayan aikin yankewa masu inganci.

CHENGDU HUAXIN CEMENTED CARBIDE CO.,LTD ƙwararrun masu kaya ne kuma masu ƙera susamfuran tungsten carbide,kamar wukake masu saka carbide don aikin katako, da kuma carbidewukake masu zagayedonsandunan tace taba da sigari, wukake zagaye don yanke kwali mai laushi,ruwan reza mai ramuka uku/ruwan wukake masu ramuka don marufi, tef, yanke fim mai siriri, ruwan wukake masu yanke fiber don masana'antar yadi da sauransu.

Tare da ci gaban da aka samu sama da shekaru 25, an fitar da kayayyakinmu zuwa Amurka, Rasha, Kudancin Amurka, Indiya, Turkiyya, Pakistan, Ostiraliya, Kudu maso Gabashin Asiya da sauransu. Tare da inganci mai kyau da farashi mai kyau, abokan cinikinmu sun amince da halayenmu na aiki tukuru da amsawa. Kuma muna son kafa sabbin alaƙar kasuwanci da sabbin abokan ciniki.

Tuntube mu a yau kuma za ku ji daɗin fa'idodin inganci da ayyuka masu kyau daga samfuranmu!

Tambayoyin gama gari na abokan ciniki da amsoshin Huaxin

Wannan ya dogara da yawan da ake buƙata, galibi kwana 5-14. A matsayinta na mai kera ruwan wukake na masana'antu, Huaxin Cement Carbide tana tsara samar da su ta hanyar oda da buƙatun abokan ciniki.

Yawanci makonni 3-6, idan kuna buƙatar wukake na inji ko ruwan wukake na masana'antu waɗanda ba a cikin kaya a lokacin siyan ba. Nemo Sharuɗɗan Siyayya & Isarwa na Sollex a nan.

idan kuna buƙatar wukake na inji ko ruwan wukake na masana'antu waɗanda ba a cikin kaya a lokacin siyan ba. Nemo Sharuɗɗan Siyayya & Isarwa na Sollexnan.

Yawanci T/T, Western Union...ajiyar kuɗi ta farko, Duk umarni na farko daga sabbin abokan ciniki ana biya su kafin lokaci. Ana iya biyan ƙarin umarni ta hanyar takardar kuɗi...tuntuɓe mudon ƙarin sani

Eh, tuntuɓe mu, Ana samun wukake na masana'antu a nau'uka daban-daban, ciki har da wukake masu zagaye a sama, waɗanda aka yi da kauri a ƙasa, wukake masu hakora/hakora, wukake masu huda da'ira, wukake madaidaiciya, wukake masu guillotine, wukake masu kaifi, wukake masu reza mai kusurwa huɗu, da kuma wukake masu siffar trapezoidal.

Domin taimaka muku samun mafi kyawun ruwan wukake, Huaxin Cement Carbide na iya ba ku samfuran ruwan wukake da yawa don gwadawa a lokacin samarwa. Don yankewa da canza kayan da suka dace kamar fim ɗin filastik, foil, vinyl, takarda, da sauransu, muna ba da ruwan wukake masu juyawa ciki har da ruwan wukake masu slotted da ruwan wukake masu ramuka uku. Aiko mana da tambaya idan kuna sha'awar ruwan wukake na inji, kuma za mu ba ku tayi. Samfuran wukake da aka yi musamman ba su samuwa amma kuna maraba da yin odar mafi ƙarancin adadin oda.

Akwai hanyoyi da yawa da za su tsawaita tsawon rai da kuma tsawon rayuwar wukake da wukake na masana'antu da ke cikin ajiya. Tuntuɓe mu don sanin yadda marufi mai kyau na wukake na inji, yanayin ajiya, danshi da zafin iska, da ƙarin rufin za su kare wukake da kuma kiyaye aikin yanke su.

Lokacin Saƙo: Yuli-23-2025