Yadda ake yin ruwan wukake na carbide?

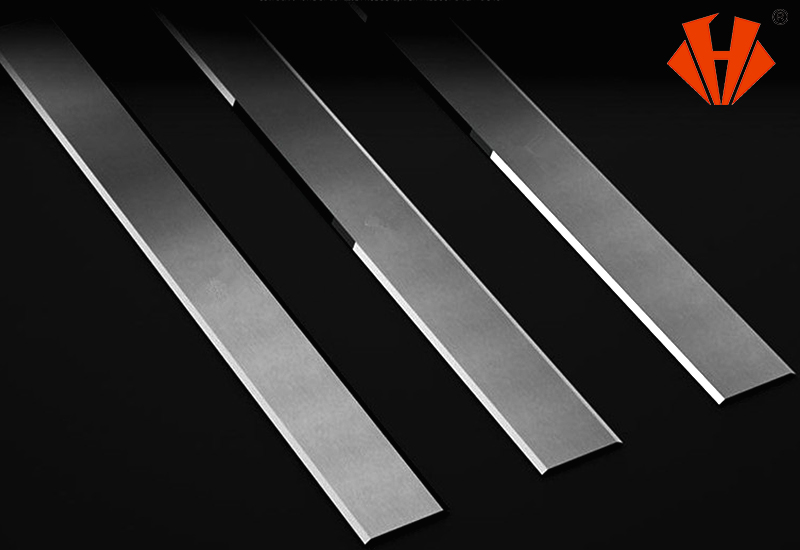

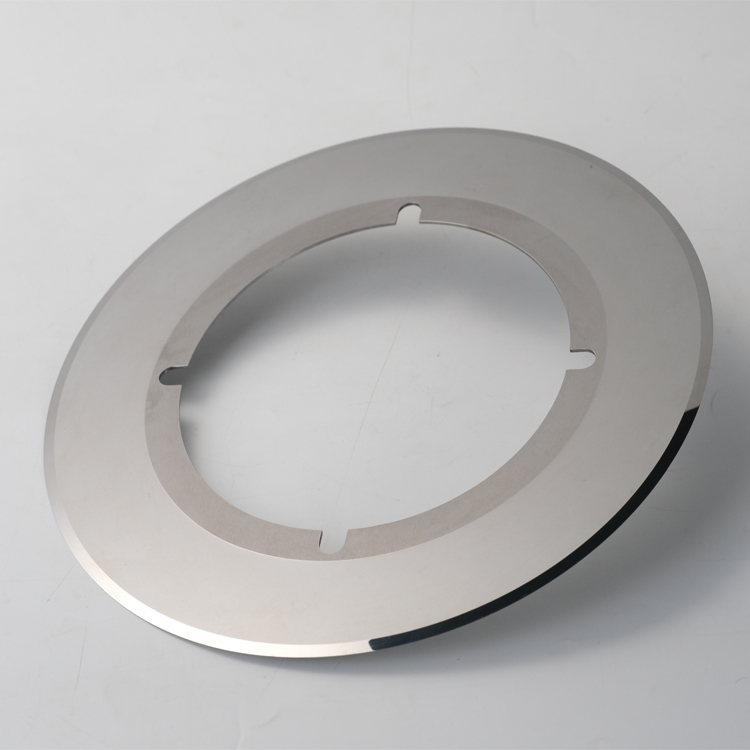

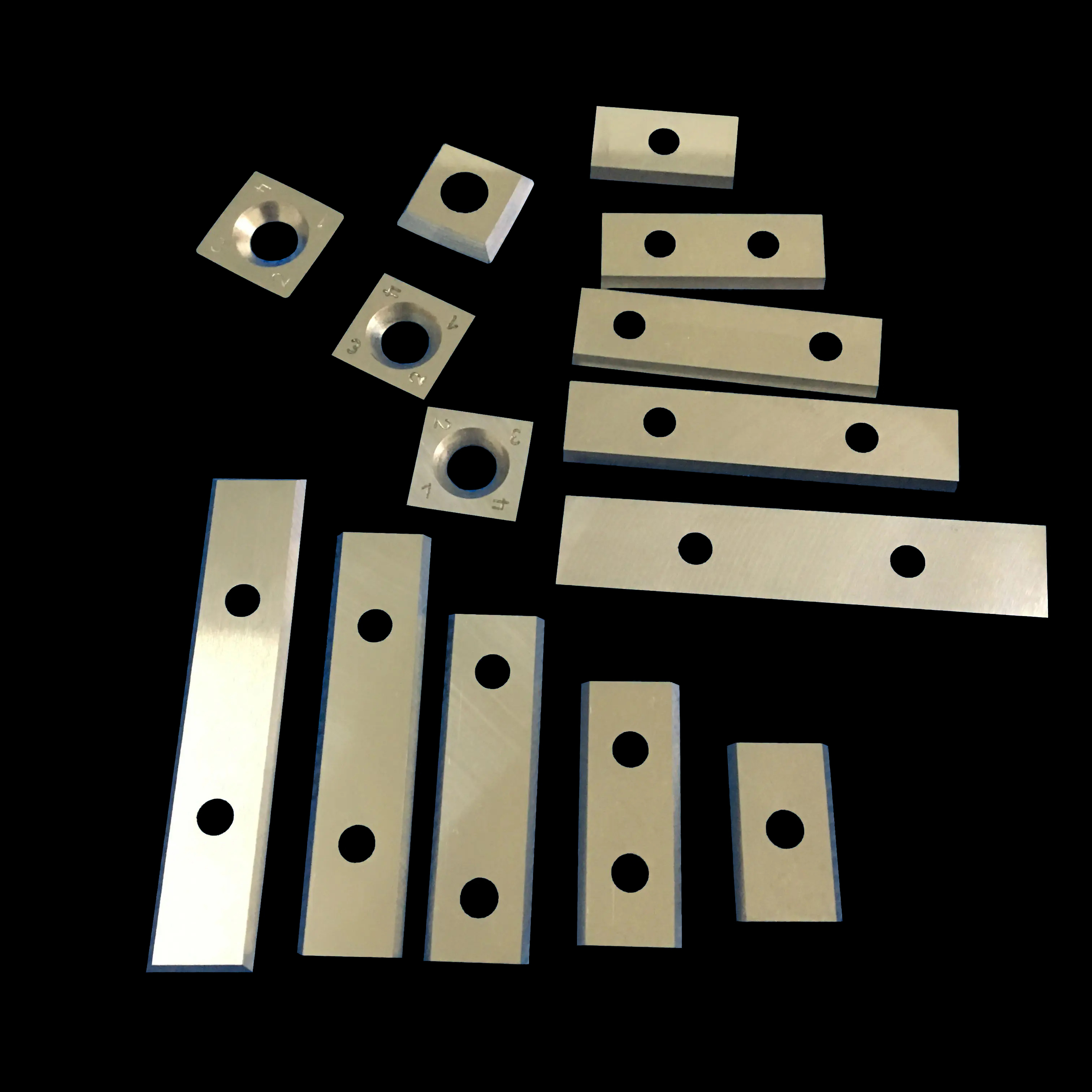

Ana daraja ruwan wukake masu siffar carbide saboda taurinsu na musamman, juriyarsu ta lalacewa, da kuma ikon kiyaye kaifi na tsawon lokaci, wanda hakan ya sa suka dace da yanke kayan da suka yi tauri.

Yawanci ana yin ruwan wukake masu siffar carbide ta amfani da hanyar da ta ƙunshi sintering foda mai siffar tungsten carbide zuwa wani siffa mai ƙarfi, sannan a yi siffa da kuma kammala ruwan wukake. Ga taƙaitaccen bayani mataki-mataki kan yadda ake samar da ruwan wukake masu siffar carbide:

1. Shirye-shiryen Kayan Danye

- Tungsten CarbideFoda: Babban kayan da ake amfani da shi a cikin ruwan wukake masu ɗauke da carbide shine tungsten carbide (WC), wanda yake da yawa kuma mai tauri na tungsten da carbon. Ana haɗa nau'in foda na tungsten carbide da ƙarfe mai ɗaurewa, yawanci cobalt (Co), don taimakawa wajen aiwatar da sintering.

- Haɗa foda: Ana haɗa garin tungsten carbide da cobalt tare don samar da cakuda iri ɗaya. Ana sarrafa haɗin a hankali don tabbatar da daidaiton abun da ke ciki don taurin ruwan wuka da ƙarfinsa da ake so.

2. Matsewa

- Gyara: Ana sanya cakuda foda a cikin wani abu ko kuma a matse shi a cikin wani siffa mai kama da juna, wanda shine tsarin ruwan wukake. Ana yin wannan yawanci a ƙarƙashin matsin lamba mai yawa a cikin wani tsari da ake kiraMatsi mai sanyi (CIP) or matsi na uniaxial.

- Siffantawa: A lokacin da ake matsawa, ana samun siffar ruwan wuka mai kauri, amma har yanzu bai yi kauri ko tauri ba. Matsewar tana taimakawa wajen narkar da cakuda foda zuwa yanayin da ake so, kamar siffar kayan aikin yankewa ko ruwan wuka.

3. Sintering

- Sintering mai zafi sosai: Bayan an danna, ruwan wukar zai yi aikin tacewa. Wannan ya ƙunshi dumama siffar da aka matse a cikin tanda a yanayin zafi da ya saba tsakanin1,400°C da 1,600°C(2552°F zuwa 2912°F), wanda ke sa ƙwayoyin foda su haɗu su samar da abu mai ƙarfi da yawa.

- Cire Maƙallin: A lokacin da ake yin siminti, ana sarrafa mannewar cobalt. Yana taimaka wa ƙwayoyin tungsten carbide su manne da juna, amma bayan an yi siminti, yana kuma taimakawa wajen bai wa ruwan wuka tauri da tauri na ƙarshe.

- Sanyaya: Bayan an yi wa ruwan toka, a hankali ana sanyaya ruwan a cikin wani yanayi mai sarrafawa don guje wa fashewa ko ɓarna.

4. Niƙa da Siffantawa

- Nika: Bayan an yi amfani da sintering, ruwan carbide sau da yawa yana da ƙarfi sosai ko kuma ba daidai ba ne, don haka ana niƙa shi daidai gwargwado ta amfani da ƙafafun gogewa na musamman ko injin niƙa. Wannan matakin yana da mahimmanci don ƙirƙirar gefen kaifi da kuma tabbatar da cewa ruwan ya cika ƙa'idodin da ake buƙata.

- Siffantawa da Tsarin Bayani: Dangane da yadda aka yi amfani da shi, ruwan wukar na iya fuskantar ƙarin siffa ko kuma siffofi. Wannan na iya haɗawa da niƙa kusurwoyi na musamman a gefen yankewa, shafa fenti, ko kuma daidaita yanayin ruwan wukar gaba ɗaya.

5. Maganin Kammalawa

- Rufin Fuskar (Zaɓi ne): Wasu ruwan wukake masu amfani da carbide suna samun ƙarin magani, kamar shafa kayan aiki kamar titanium nitride (TiN), don inganta tauri, juriya ga lalacewa, da rage gogayya.

- Gogewa: Domin ƙara inganta aiki, ana iya goge ruwan wukake don samun santsi da kuma saman da aka gama wanda ke rage gogayya da kuma inganta ingancin yankewa.

6. Sarrafa Inganci da Gwaji

- Gwajin Tauri: Yawanci ana gwada taurin ruwan wukake don tabbatar da cewa ya cika ƙa'idodin da ake buƙata, tare da gwaje-gwajen da aka saba yi, ciki har da gwajin taurin Rockwell ko Vickers.

- Dubawa Mai Girma: Daidaito yana da mahimmanci, don haka ana duba girman ruwan wukake don tabbatar da cewa sun dace da daidai juriya.

- Gwajin Aiki: Don takamaiman aikace-aikace, kamar yankewa ko yankewa, ruwan wukake na iya yin gwaji na gaske don tabbatar da cewa yana aiki kamar yadda aka nufa.

HUAXIN CARBIDE MAI SUMMITA yana ba da wuƙaƙe da ruwan wukake masu tsada na tungsten carbide ga abokan cinikinmu daga masana'antu daban-daban a faɗin duniya. Ana iya tsara ruwan wukake don dacewa da injina da ake amfani da su a kusan kowace aikace-aikacen masana'antu. Ana iya daidaita kayan ruwan wukake, tsawon gefen da bayanan martaba, jiyya da rufin don amfani da kayan masana'antu da yawa.

Da zarar ruwan wukake sun wuce duk gwaje-gwajen inganci, suna shirye don amfani a aikace-aikace daban-daban na masana'antu, kamar aikin ƙarfe, marufi, ko wasu ayyukan yankewa inda juriya da kaifi mai yawa suke da mahimmanci.

Lokacin Saƙo: Nuwamba-25-2024