Kayan ƙarfe da aka yi da wani abu mai tauri na ƙarfe mai jurewa da ƙarfe mai ɗaurewa ta hanyar amfani da ƙarfe mai ƙullawa. Carbide mai siminti yana da jerin kyawawan halaye kamar tauri mai ƙarfi, juriyar sawa, ƙarfi mai kyau da tauri, juriyar zafi da juriyar tsatsa, musamman ma ƙarfinsa mai ƙarfi da juriyar sawa, waɗanda ba sa canzawa ko da a zafin jiki na 500 °C, har yanzu yana da tauri mai girma a 1000℃. Ana amfani da Carbide sosai a matsayin kayan aiki, kamar kayan aikin juyawa, masu yanke niƙa, masu shiryawa, injinan haƙa, kayan aiki masu ban sha'awa, da sauransu, don yanke ƙarfe mai siminti, ƙarfe marasa ƙarfe, robobi, zare masu sinadarai, graphite, gilashi, dutse da ƙarfe na yau da kullun, kuma ana iya amfani da shi don yanke kayan da ke da wahalar amfani da su kamar ƙarfe mai jurewa zafi, bakin ƙarfe, ƙarfe mai yawa na manganese, ƙarfe na kayan aiki, da sauransu. Saurin yanke sabbin kayan aikin carbide yanzu ya ninka na ƙarfe mai ƙarfe ɗaruruwa sau ɗari.

Amfani da siminti carbide

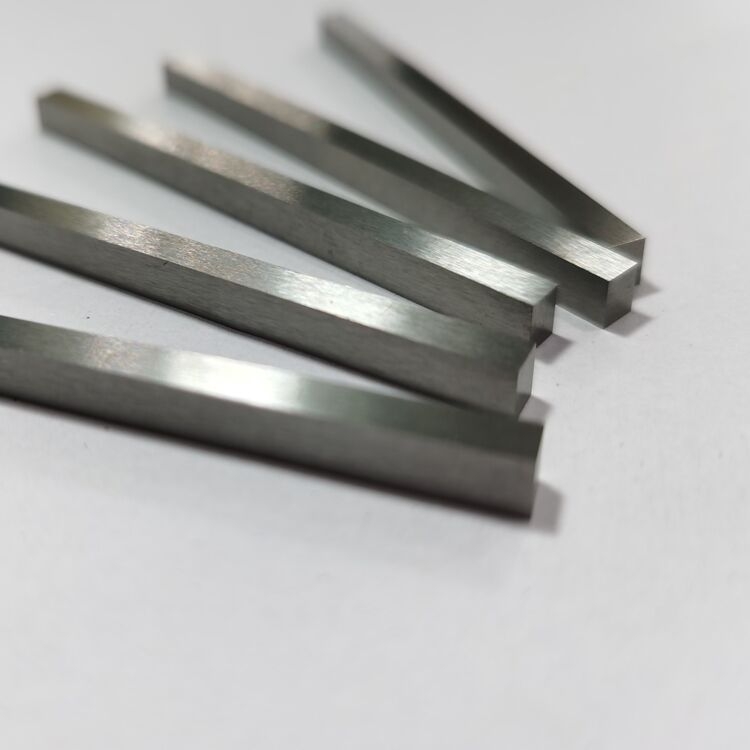

(1) Kayan aiki

Carbide shine mafi girman adadin kayan aiki, wanda za'a iya amfani dashi don yin kayan aikin juyawa, masu yanke niƙa, masu shiryawa, injinan haƙa, da sauransu. Daga cikinsu, tungsten-cobalt carbide ya dace da sarrafa guntu na ƙarfe da ƙarfe marasa ƙarfe da sarrafa kayan da ba na ƙarfe ba, kamar ƙarfe mai siminti, tagulla mai siminti, bakelite, da sauransu; tungsten-titanium-cobalt carbide ya dace da sarrafa ƙarfe mai ƙarfe na dogon lokaci kamar ƙarfe. Injin sarrafa guntu. Daga cikin ƙarfe masu kama da juna, waɗanda ke da ƙarin sinadarin cobalt sun dace da injin sarrafa ƙarfe mai ƙarfi, kuma waɗanda ke da ƙarancin sinadarin cobalt sun dace da kammalawa. Carbides masu siminti na gabaɗaya suna da tsawon rai fiye da sauran carbide masu siminti don kayan da ke da wahalar amfani da su kamar bakin ƙarfe.

(2) Kayan ƙira

Ana amfani da carbide mai siminti galibi don kayan aikin sanyi kamar su zanen sanyi, naushin sanyi, fitar da iska mai sanyi, da kuma kayan aikin tuƙi mai sanyi.

Ana buƙatar na'urorin ɗaukar kaya masu sanyi na Carbide don samun ƙarfin tasiri mai kyau, ƙarfin karyewa, ƙarfin gajiya, ƙarfin lanƙwasawa da juriya mai kyau a ƙarƙashin yanayin aiki mai jure lalacewa ko tasirin ƙarfi. Yawanci ana amfani da ma'aunin ƙarfe mai matsakaici da babba da matsakaici da kauri, kamar YG15C.

Gabaɗaya dai, alaƙar da ke tsakanin juriyar sawa da kuma taurin carbide mai siminti abu ne mai karo da juna: ƙaruwar juriyar sawa zai haifar da raguwar tauri, kuma ƙaruwar tauri ba makawa zai haifar da raguwar juriyar sawa. Saboda haka, lokacin zaɓar matakan ƙarfe, ya zama dole a cika takamaiman buƙatun amfani bisa ga abin sarrafawa da yanayin aiki.

Idan matakin da aka zaɓa yana da saurin fashewa da lalacewa da wuri yayin amfani, ya kamata a zaɓi matakin da ya fi ƙarfin ƙarfi; idan matakin da aka zaɓa yana da saurin lalacewa da lalacewa da wuri yayin amfani, ya kamata a zaɓi matakin da ya fi ƙarfin ƙarfi da juriyar lalacewa. . Maki masu zuwa: YG15C, YG18C, YG20C, YL60, YG22C, YG25C Daga hagu zuwa dama, taurin yana raguwa, juriyar lalacewa yana raguwa, kuma taurin yana ƙaruwa; akasin haka, akasin haka gaskiya ne.

(3) Kayan aikin aunawa da sassan da ba sa jure lalacewa

Ana amfani da Carbide don yin amfani da kayan da ke jure lalacewa da sassan kayan aikin aunawa, daidaiton bearings na niƙa, faranti na jagora da sandunan jagora na niƙa marasa tsakiya, saman lathes da sauran sassan da ke jure lalacewa.

Karafan ƙarfe galibi ƙarfe ne na rukuni na ƙarfe, galibi suna da sinadarin cobalt da nickel.

Lokacin ƙera carbide mai siminti, girman barbashi na foda ɗin da aka zaɓa yana tsakanin microns 1 da 2, kuma tsarkin yana da yawa sosai. Ana haɗa kayan da aka zaɓa bisa ga rabon abun da aka tsara, kuma ana ƙara barasa ko wani abu mai ƙarfi a cikin niƙa mai jika a cikin injin niƙa mai jika don ya haɗa su gaba ɗaya kuma ya niƙa. A tace cakuda. Sannan, a yayyafa cakuda, a matse shi, sannan a dumama shi zuwa zafin da ke kusa da wurin narkewar ƙarfe mai ɗaure (1300-1500 °C), matakin taurare da ƙarfe mai ɗaure za su samar da ƙarfe mai ɗaurewa. Bayan sanyaya, matakan taurare suna rarrabawa a cikin grid ɗin da aka haɗa da ƙarfe mai ɗaurewa kuma suna da alaƙa da juna don samar da cikakken ƙarfi. Taurin carbide mai ɗaurewa ya dogara da abun da ke cikin matakin taurare da girman hatsi, wato, mafi girman abun da ke cikin matakin taurare da kuma mafi kyawun hatsi, mafi girman taurin. Taurin carbide mai ɗaurewa ana ƙaddara shi ta hanyar ƙarfe mai ɗaurewa. Mafi girman abun da ke cikin ƙarfe mai ɗaurewa, mafi girman ƙarfin lanƙwasawa.

A shekarar 1923, Schlerter na Jamus ya ƙara kashi 10% zuwa 20% na cobalt a cikin foda mai kama da tungsten carbide a matsayin abin ɗaurewa, kuma ya ƙirƙiro sabon ƙarfe mai kama da tungsten carbide da cobalt. Taurin yana biye da lu'u-lu'u kawai. An yi carbide na farko da aka yi da siminti. Lokacin da ake yanka ƙarfe da kayan aiki da aka yi da wannan ƙarfe, gefen yankewa zai lalace da sauri, har ma gefen yankewa zai fashe. A shekarar 1929, Schwarzkov a Amurka ya ƙara wani adadin carbide mai kama da tungsten carbide da titanium carbide a cikin abun da aka haɗa na asali, wanda ya inganta aikin kayan aikin a cikin yanke ƙarfe. Wannan wani nasara ce a tarihin haɓaka carbide mai kama da siminti.

Carbide mai siminti yana da jerin kyawawan halaye kamar ƙarfin tauri, juriyar sawa, ƙarfi da tauri mai kyau, juriyar zafi da juriyar tsatsa, musamman ƙarfin tauri da juriyar sawa, waɗanda ba sa canzawa ko da a zafin jiki na 500 °C, har yanzu yana da babban tauri a 1000℃. Ana amfani da Carbide sosai a matsayin kayan aiki, kamar kayan aikin juyawa, masu yanke niƙa, masu shiryawa, injinan motsa jiki, kayan aiki masu ban sha'awa, da sauransu, don yanke ƙarfe, ƙarfe marasa ƙarfe, robobi, zare masu sinadarai, graphite, gilashi, dutse da ƙarfe na yau da kullun, kuma ana iya amfani da shi don yanke kayan da ke da wahalar amfani da su kamar ƙarfe mai jure zafi, bakin ƙarfe, ƙarfe mai yawa na manganese, ƙarfe na kayan aiki, da sauransu. Saurin yanke sabbin kayan aikin carbide yanzu ya ninka na ƙarfe mai jure zafi sau ɗari.

Ana iya amfani da Carbide don yin kayan aikin haƙa dutse, kayan aikin haƙa ma'adinai, kayan aikin haƙa, kayan aikin aunawa, sassan da ba sa jure lalacewa, abubuwan goge ƙarfe, layukan silinda, bearings masu daidaito, nozzles, molds na ƙarfe (kamar injin zana waya, injinan ƙulli, injinan goro, da kuma nau'ikan maƙallan ɗaurewa daban-daban, kyakkyawan aikin carbide mai siminti ya maye gurbin injinan ƙarfe na baya).

Daga baya, an fitar da carbide mai rufi da siminti. A shekarar 1969, Sweden ta yi nasarar ƙirƙiro kayan aiki mai rufi da titanium carbide. Tushen kayan aikin shine tungsten-titanium-cobalt carbide ko tungsten-cobalt carbide. Kauri na murfin titanium carbide da ke saman shine microns kaɗan kawai, amma idan aka kwatanta da irin wannan nau'in kayan aikin ƙarfe, Rayuwar sabis ɗin tana ƙaruwa da sau 3, kuma saurin yankewa ya ƙaru da kashi 25% zuwa 50%. A shekarun 1970, an sami ƙarni na huɗu na kayan aiki masu rufi don yanke kayan da ke da wahalar yin amfani da su.

Ta yaya ake yin simintin simintin carbide?

Carbide mai siminti abu ne da aka yi da ƙarfe mai ƙarfi na carbides da ƙarfe mai ɗaurewa na ƙarfe ɗaya ko fiye masu tsauri.

Mƙasashe masu samar da kayayyaki masu yawa

Akwai ƙasashe sama da 50 a duniya da ke samar da carbide mai siminti, wanda jimillar fitarwar sa ta kai 27,000-28,000t-. Manyan masu samar da su sune Amurka, Rasha, Sweden, China, Jamus, Japan, Burtaniya, Faransa, da sauransu. Kasuwar carbide mai siminti a duniya ta cika sosai. Gasar kasuwa tana da matuƙar ƙarfi. Masana'antar carbide mai siminti a China ta fara samun ƙarfi a ƙarshen shekarun 1950. Daga shekarun 1960 zuwa 1970, masana'antar carbide mai siminti a China ta bunƙasa cikin sauri. A farkon shekarun 1990, jimillar ƙarfin samar da carbide mai siminti a China ya kai 6000t, kuma jimillar fitarwar carbide mai siminti ya kai 5000t, wanda ya zo na biyu a Rasha da Amurka, yana matsayi na uku a duniya.

Mai yanka WC

①Tungsten da cobalt carbide mai siminti

Babban abubuwan da aka haɗa sune tungsten carbide (WC) da binder cobalt (Co).

Matsayinsa ya ƙunshi "YG" ("tauri da cobalt" a cikin Pinyin na kasar Sin) da kuma kashi na matsakaicin abun ciki na cobalt.

Misali, YG8 yana nufin matsakaicin WCo = 8%, sauran kuma shine tungsten-cobalt carbide na tungsten carbide.

Wukake na TIC

②Tungsten-titanium-cobalt carbide

Manyan sinadaran sune tungsten carbide, titanium carbide (TiC) da cobalt.

Matsayinsa ya ƙunshi "YT" ("mai tauri, titanium" haruffa biyu a cikin prefix ɗin Pinyin na kasar Sin) da matsakaicin abun ciki na titanium carbide.

Misali, YT15 yana nufin matsakaicin WTi=15%, sauran kuma shine tungsten carbide da tungsten-titanium-cobalt carbide tare da sinadarin cobalt.

Kayan Aikin Tungsten Titanium Tantalum

③Tungsten-titanium-tantalum (niobium) siminti carbide

Manyan sinadaran sune tungsten carbide, titanium carbide, tantalum carbide (ko niobium carbide) da kuma cobalt. Irin wannan carbide mai siminti ana kuma kiransa da janar carbide mai siminti ko kuma carbide mai siminti na duniya.

An haɗa ma'auninsa da "YW" (ƙarfin kalmomin Sinanci na "hard" da "wan") tare da lambar jeri, kamar YW1.

Halayen Aiki

Saka-sayen Carbide da aka haɗa

Babban tauri (86~93HRA, daidai da 69~81HRC);

Kyakkyawan taurin zafi (har zuwa 900 ~ 1000℃, kiyaye 60HRC);

Kyakkyawan juriya ga abrasion.

Kayan aikin yanke carbide sun fi sauri sau 4 zuwa 7 fiye da ƙarfe mai sauri, kuma tsawon rayuwar kayan aikin ya ninka sau 5 zuwa 80. A fannin kera ƙira da kayan aikin aunawa, tsawon rayuwar sabis ya ninka na ƙarfe mai ƙarfe sau 20 zuwa 150. Yana iya yanke kayan aiki masu tauri na kimanin HRC 50.

Duk da haka, carbide mai siminti yana da rauni kuma ba za a iya yin shi da injin ba, kuma yana da wuya a yi kayan aiki masu tsari tare da siffofi masu rikitarwa. Saboda haka, galibi ana yin ruwan wukake masu siffofi daban-daban, waɗanda ake sanyawa a jikin kayan aiki ko jikin mold ta hanyar walda, haɗawa, mannewa na inji, da sauransu.

Sandar siffa ta musamman

Sintering

Tsarin simintin simintin simintin simintin siminti shine a matse foda a cikin billet, sannan a shiga cikin tanda mai simintin don dumama zuwa wani zafin jiki (zafin simintin ...

Tsarin haɗa simintin carbide mai siminti za a iya raba shi zuwa matakai huɗu na asali:

1: A matakin cire sinadarin da ke samar da sinadarin da kuma kafin a yi masa sintering, jikin da ke cikin sintering yana canzawa kamar haka:

Cire sinadarin gyaran fuska, tare da ƙaruwar zafin jiki a matakin farko na gyaran fuska, sinadarin gyaran fuska yana ruɓewa ko tururi a hankali, kuma jikin da aka lalata ba a cire shi ba. Nau'in, adadi da tsarin gyaran fuska sun bambanta.

Ana rage yawan sinadarin oxides da ke saman foda. A zafin sintering, hydrogen na iya rage sinadarin cobalt da tungsten. Idan aka cire sinadarin da ke samar da shi a cikin injin tsabtace iska sannan aka yi masa sintiri, tasirin carbon-oxygen ba shi da ƙarfi. Ana kawar da damuwar da ke tsakanin ƙwayoyin foda a hankali, foda na ƙarfe da ke haɗe ya fara murmurewa da sake yin amfani da shi, yaduwar saman ta fara faruwa, kuma ƙarfin briquetting ya inganta.

2: Matakin sintering mai ƙarfi (800℃–zafin jiki mai ƙarfi)

A zafin jiki kafin bayyanar matakin ruwa, ban da ci gaba da aiwatar da matakin da ya gabata, amsawar matakin ƙarfi da yaɗuwa suna ƙaruwa, kwararar filastik tana ƙaruwa, kuma jikin da aka niƙa yana raguwa sosai.

3: Matakin sintering na ruwa (zafin jiki na eutectic - zafin sintering)

Idan matakin ruwa ya bayyana a cikin jikin da aka niƙa, raguwar ta cika da sauri, sannan a biyo baya da canjin kristal don samar da tsari da tsarin ƙarfe na asali.

4: Matakin sanyaya (zafin sintering - zafin ɗaki)

A wannan matakin, tsari da tsarin mataki na gami suna da wasu canje-canje tare da yanayi daban-daban na sanyaya. Ana iya amfani da wannan fasalin don dumama simintin carbide don inganta halayensa na zahiri da na inji.

Lokacin Saƙo: Afrilu-11-2022